Table of Contents

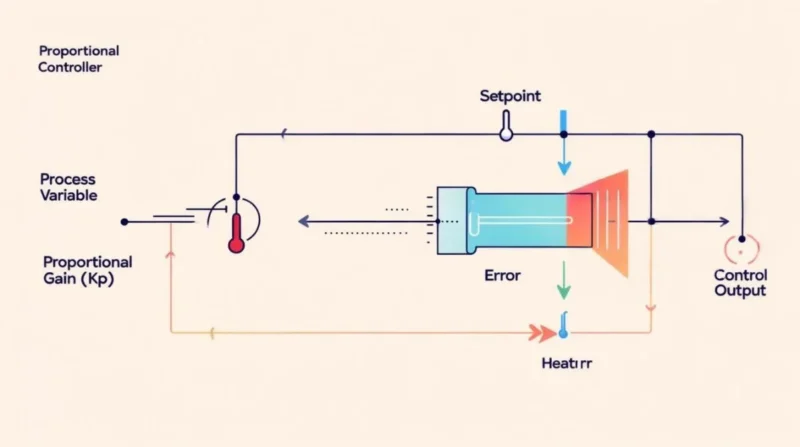

At its simplest, a proportional controller (often called “P controller”) is a device that adjusts its output in direct relation to the error, you know, the gap between where you want something to be (set point) and where it actually is (process variable). If you’re heating water and the temp is lower than you want, the controller raises the heater in proportion to how cold it is; the wider the gap, the more powerful the response.

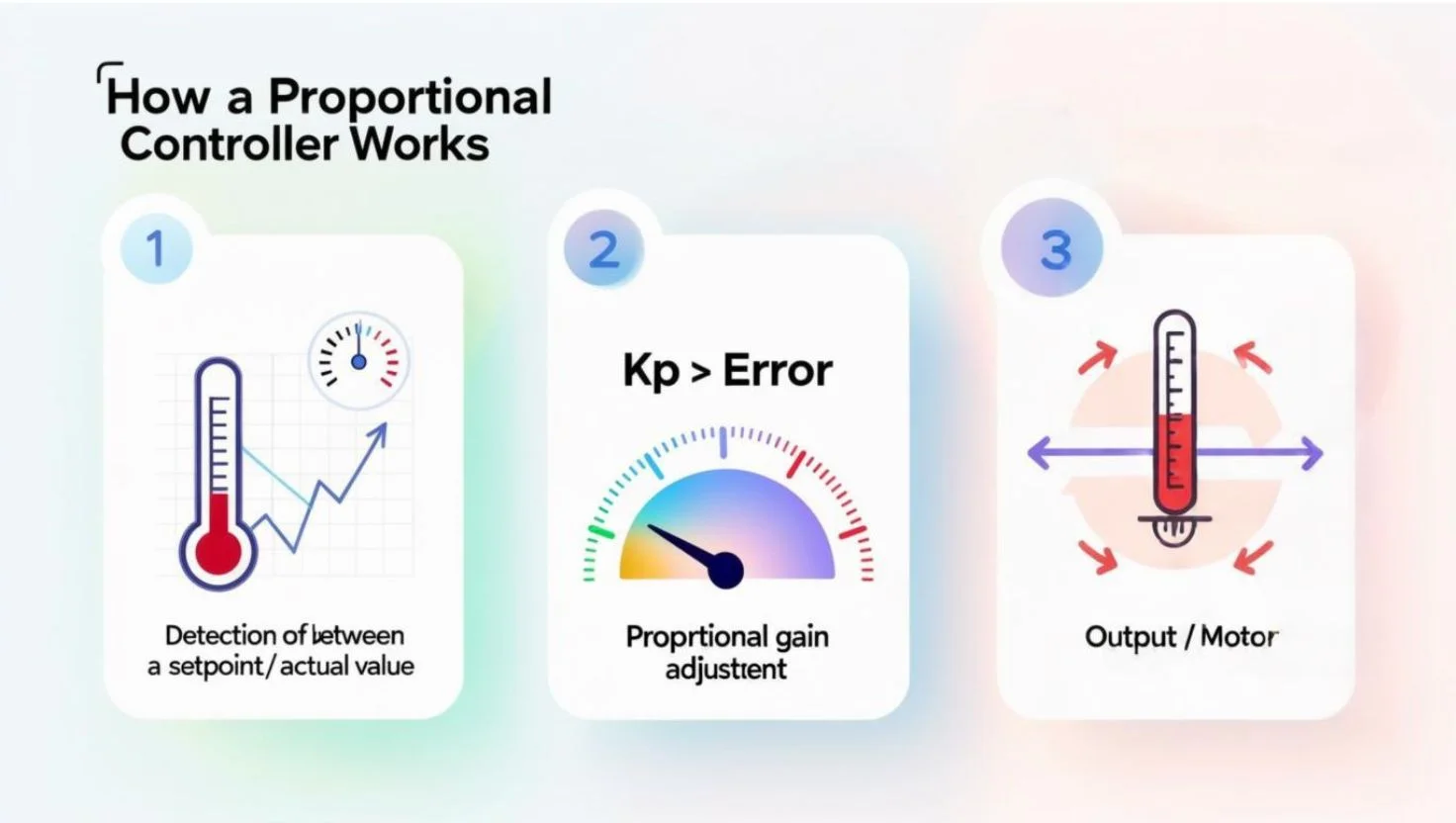

How does it work?

- Error detection: The controller constantly measures the difference.

error = setpoint – process variable. - Multiply by gain: It multiplies this error by a constant Kₚ (proportional gain). When the error is large and the Kₚ value is high, the controller responds more strongly.

- Produce control signal: This output adjusts your system more or less heating, throttle, pressure, etc.

- Repeat continuously: The loop runs fast, seeing updated error and making new moves.

Mathematically:

u(t) = Kₚ × e(t) + bias, where bias (sometimes called p₀) helps the system do something even when the error hits zero.

Why Use It?

- Simple and predictable: It acts smoothly, not jumping between on/off extremes like simpler thermostats.

- Faster than on-off: Adjustments happen as needed, so your system stabilizes faster with fewer swings.

- Great for many tasks: Used in heating systems, cruise control, water level, pressure, flow, and even old mechanical governors like fly-ball ones.

Key Terms of Proportional Controller

- Setpoint (SP): Your goal value, temperature, speed, etc.

- Process Variable (PV): The actual condition, like the current temperature or speed.

- Error (e(t)): SP minus PV, the key input.

- Proportional Gain (Kₚ): How aggressively the controller reacts.

- Bias/P₀: An offset to get the system moving even when the error is zero.

- Proportional Band: Range over which control moves from minimum to maximum. (Lower band = higher gain).

Applications of Proportional Controllers

Industrial Automation

Proportional controllers are commonly used in factories to keep things like temperature, pressure, and liquid flow steady and at the right level.

HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, these controllers help control room temperature and airflow to make sure indoor spaces stay comfortable.

Robotics

Proportional controllers help robots move smoothly by accurately managing motor speed and position, making their movements more precise and stable.

Automotive Industry

In cars, proportional controllers are used in areas like engine management, braking, and air conditioning to improve how the vehicle runs and keep it safe.

Advantages & Dis-advantages

Advantages:

- Faster reaction to changes than on–off systems.

- Simple implementation, either in software or hardware.

- Offers better stability than on-off control, with reduced overshoot and less frequent cycling.

Dis-advantages:

- Steady state error (offset): The System can’t fully reach the setpoint some error always remains.

- Overshoot/undershoot risks: Too strong a gain may cause the system to go past or bounce around the setpoint.

- Gain tuning trade-offs: High gain improves response, but can make the system unstable. Low gain keeps it stable, but slow.

Tuning Guide

To tune the gain Kₚ:

- Start with a small Kₚ.

- Gradually increase until the system shows small oscillations.

- Reduce Kₚ to about half that value; this gives a balanced response with minimal overshoot.

- Test performance with disturbances (like turning the heater off briefly or adding a load) and fine-tune.

Real World Examples

Adaptive Cruise Control

Your car measures distance to the vehicle ahead and adjusts throttle or brakes smoothly to keep a safe separation. More error = heavier throttle/braking.

Heating Systems

Room temperature below setpoint; The heating kicks in proportionally to close the gap, but may never hit exactly if not tuned right.

Water Tank Level

Sensors check the water level; valves open or close proportionally to maintain the right level.

Mechanical Governor

The fly-ball governor in engines uses spinning weights to regulate the throttle based on changes in engine speed.

Why Steady State Error Happens?

Because u(t) depends on error, if PV ever equals SP, error hits zero, and input drops to a baseline. That means output can’t drive PV exactly to SP, making a small, constant gap, and that’s your steady state error.

When to Choose Proportional vs. PID

- Proportional only (P): Simple, okay if a small offset is acceptable, and the system isn’t too sensitive.

- PID controller: Adds integral term (fixes steady state error) and derivative term (predicts future error) so it corrects faster and more accurately.

If you need high precision, like in industrial production, chemical processes, or critical automation, PID is usually better. But for basic tasks, P is only easier and more cost-effective.

Proportional Control in Everyday Terms

Think of driving with a cruise control that only adjusts speed when you’re slow or fast, not smart enough to anticipate hills (no derivative) or correct drift over time (no integral). It’s simple, but fine if you’re okay with small speed swings.

Conclusion

A proportional controller steadily adjusts output based on how far off you are from your target. It’s simple, fast, and smooth compared to the on/off systems, but it leaves a small steady error. Tuning involves picking the right gain, not too high to avoid fluctuation, not too low to prevent slowness. Used widely from car cruise controls to heaters and industrial processes, it’s a foundational part of control theory. For pinpoint accuracy, systems often upgrade to full PID, but when simplicity and cost matter, a P controller does the job well.