Table of Contents

- 12 Surprising Facts of Milwaukee Power Tools Drill

- 1. Born from Ford’s Need in 1918

- 2. The “Hole Shooter” Shaped Modern Drills

- 3. Packed with PowerState Brushless Motors

- 4. AutoStop™ Control for Safety

- 5. ONE‑KEY™ Digital Tracking & Customization

- 6. First Hammer Drill with Dust Extraction

- 7. Compact Yet Beastly Power

- 8. The World’s First Triggerless AI Drill

- 9. A Drill for Cabinetry Pros

- 10. RedLithium™ Batteries Mean More Work

- 11. Fully American Innovation

- 12. Built on a Century of Innovation

- Why This Matters for You?

- Milwaukee Power Tools Drill Maintenance Tips

- Clean the drill after every use

- Care for the battery (M12 or M18)

- Lubricate the chuck and moving parts

- Use the correct settings for each job

- Let the drill cool after heavy use

- Update firmware (for ONE-KEY™ models)

- Check for loose screws and casing

- Avoid overtightening screws

- Store in a temperature-controlled space

- Schedule an annual maintenance check

- FAQ

- Compare With Other Top Brands

- Conclusion

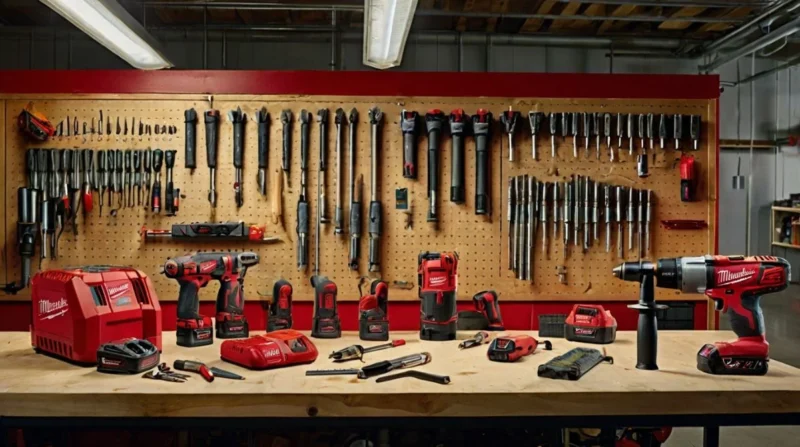

Milwaukee Tools has built a legendary reputation around the “Milwaukee Power Tools drill,” but even experienced users might be surprised by how innovative and rich its story truly is. From century-old breakthroughs to futuristic AI features, here are 12 eye-opening details you’ll find useful, explained in simple terms.

12 Surprising Facts of Milwaukee Power Tools Drill

1. Born from Ford’s Need in 1918

Milwaukee didn’t start with hammers or saws; it began solving a real problem. Henry Ford wanted a lightweight, portable drill to speed up assembly lines. That led to the first “Hole-Shooter” in 1918: a handheld ¼‑inch electric drill that weighed just 5 lb. It changed the game for one-handed drilling.

2. The “Hole Shooter” Shaped Modern Drills

This early model influenced how drills are made today. Its compact size, keyless chuck, and easy grip became core features in modern drills, especially in Milwaukee’s designs.

3. Packed with PowerState Brushless Motors

Milwaukee’s FUEL line uses POWERSTATE brushless motors. These deliver more torque, less heat, and longer life with no worn brushes to replace. That boosts durability for heavy jobs.

4. AutoStop™ Control for Safety

The M18 FUEL ½” Hammer Drill/Driver, model 2906‑20, features AutoStop™. It stops the drill instantly if it binds, reducing kickback and preventing accidents. Plus, it lets users set sensitivity levels through the ONE‑KEY™ app.

5. ONE‑KEY™ Digital Tracking & Customization

ONE‑KEY™ is Milwaukee’s smart‑tool system. It lets you customize settings, track location, and lock your tool if it’s stolen. It’s like having a tool-management dashboard at your fingertips.

6. First Hammer Drill with Dust Extraction

The M18 FUEL SDS Plus Rotary “HammerVac” is a rare beast: a hammer drill with built-in HEPA dust extraction. It vacuums debris as you drill, saving time on cleanup and improving job-site health.

7. Compact Yet Beastly Power

Milwaukee’s drills are smaller than you’d expect. The FUEL ½” hammer drill is only 6.9″ long but delivers enough power to drill 2‑9/16″ holes in hardwood. Small size, big muscle.

8. The World’s First Triggerless AI Drill

The latest M18 AI Triggerless Drill starts drilling when the bit touches material. It uses AI to control torque and stops automatically no trigger pull, no guesswork. This is next-level smart drilling.

9. A Drill for Cabinetry Pros

Journalists raved about the ultra-compact M12 Fuel Installation Drill/Driver (2 lb.): it has four swappable heads, right angle, offset, 3/8″ chuck, and 1/4″ hex—so you can install IKEA cabinets or door hardware with ease.

Bonus Resource: Rivets & Precision Assembly

If your project involves metalworking or clean mechanical joints, learning how to use rivets properly is a game-changer. According to Wordle Magazine’s guide on rivets and tools, “mastering rivet tools ensures stronger, more permanent joints, especially in cabinetry, sheet metal, and DIY frames.” It’s a perfect skillset to pair with your Milwaukee drill for pro-level results.

10. RedLithium™ Batteries Mean More Work

Milwaukee’s RedLithium batteries (12 V M12 and 18 V M18) offer more runtime, stronger power under load, and better temperature control. They’re designed to work hard, last long, and stay reliable in tough conditions.

11. Fully American Innovation

Even though Milwaukee now produces tools worldwide, its core manufacturing and R&D remain in the U.S. Since 1924, the company has consistently pumped money into Wisconsin plants, earning a reputation for quality and innovation.

12. Built on a Century of Innovation

Milwaukee continuously builds on a legacy of tool breakthroughs:

- In 1935, they introduced a combo hammer drill that could switch to regular drilling mode.

- In 1951, they invented the first portable reciprocating saw with patented tech that reduced recoil.

- By 2012, cordless tools with REDLINK electronics and FUEL motors crushed expectations.

![]()

Why This Matters for You?

Knowing these facts can help you choose the right Milwaukee power tools drill for your needs:

- Safety: AutoStop and AI triggers reduce risk.

- Smart control: ONE‑KEY™ settings streamline your work.

- Efficiency: Dust extraction and convertible heads save time.

- Comfort: Compact, lightweight designs reduce fatigue.

- Trust: 100 years of innovation backed by advanced battery and motor tech.

Milwaukee Power Tools Drill Maintenance Tips

Clean the drill after every use

- Wipe with a dry microfiber cloth.

- Use compressed air for vents and tight spots.

- Avoid water or harsh cleaners.

Care for the battery (M12 or M18)

- Charge fully before storing.

- Store in a dry, cool place.

- Don’t overcharge or let it drain completely.

- Always use original Milwaukee RedLithium batteries.

Lubricate the chuck and moving parts

- Apply a few drops of machine oil inside the chuck.

- Rotate to spread oil and wipe off excess.

- Repeat every few months or when stiff.

Use the correct settings for each job

- Use drill mode for holes, screw mode for fasteners, hammer mode for masonry.

- Match torque to material to reduce motor strain.

Let the drill cool after heavy use

- Avoid back-to-back sessions without rest.

- Allow 10–15 minutes of cooling time.

Update firmware (for ONE-KEY™ models)

- Connect the drill via Bluetooth in the ONE-KEY™ app.

- Keep software and firmware updated for best performance.

Check for loose screws and casing

- Inspect the handle, chuck, and battery latch monthly.

- Tighten with an appropriate screwdriver or hex tool.

Avoid overtightening screws

- Stop when resistance is felt.

- Use the torque limiter setting if available.

Store in a temperature-controlled space

- Ideal range: 10°C–25°C (50°F–77°F).

- Avoid garages, vehicles, or damp basements.

Schedule an annual maintenance check

- Inspect chuck alignment, motor health, and battery performance.

- Visit Milwaukee service centers or certified repair shops.

FAQ

Q1. Are brushless drills worth it?

Yes. Brushless motors last longer, are more efficient, and deliver consistent torque. Think 3× longer life and less maintenance.

Q2. What’s the difference between M12 and M18?

M12 is a lightweight 12‑V system for tight spaces and light work. The M18 offers more torque and power, great for heavy-duty jobs.

Q3. Is the AI-triggerless drill a game changer?

Absolutely. It replaces manual control with smart automation, which means more precision and fewer mistakes.

Compare With Other Top Brands

Want to see how Milwaukee stacks up against other tool giants? Wordle Magazine’s full guide on DeWalt Power Tools offers a detailed breakdown of DeWalt’s product lines, use cases, and advantages for both DIYers and professionals. Understanding these differences can help you make smarter buying decisions, especially if you’re comparing Milwaukee M18 vs DeWalt XR tools.

Conclusion

These aren’t just gimmicks; the innovations behind the “Milwaukee Power Tools drill” are built for real craftsmen and DIYers. From their roots in Ford’s assembly line to peace-of-mind safety features and groundbreaking AI tech, Milwaukee drills continue evolving. Whether you’re drilling in tight kitchen corners or piercing concrete, there’s likely a Milwaukee drill made for the job, and now you know why it’s so special.